Specialist Welding Systems

Ultrasonic Welding

The components usually of thin section are vibrated to achieve a clean contact with each other at the atomic level. This system is mainly employed for materials less than 2.5mm in thickness and also in the joining of plastics.

Explosive Welding

Where large areas of dissimilar materials are required to be joined this method is often employed. A controlled explosion brings the two materials into close contact to each other achieving an atomic bond whilst pushing out the contaminates.

Diffusion Welding

This method presses the two clean surfaces together whilst raising the temperature, normally carried out in an inert atmosphere to reduce possible contamination.

Thermit Welding

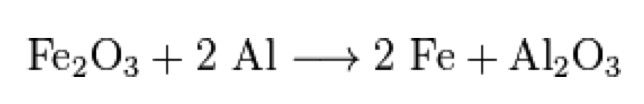

Thermit welding, also known as Exothermic welding, is an effective and highly mobile welding process that uses molten metal to permanently join the conductors. The process employs an exothermic reaction of a thermite composition to heat the metal, and requires no external source of heat or current. The chemical reaction that produces the heat is an aluminothermic reaction between aluminium powder and a metal oxide. In this process, aluminium dust reduces the oxide of another metal, most commonly iron oxide, because aluminium is highly reactive (oxygen loving). Iron (III) oxide is commonly used:

The products are aluminium oxide, free elemental iron, and a large amount of heat. The reactants are commonly powdered and mixed with a binder to keep the material solid and prevent separation.

The high heat input and metallurgical properties of the Thermit steel make the process ideal for welding high strength, high hardness steels such as those used for modern railway tracks.

Friction Stir welding

Developed by The Welding Institute this method uses a rotating tool which moves between the material faces, the frictional heat generated mechanically mixes the materials together whilst in the plastic form without melting the materials. This leads to a very low distortion weld.

The process is capable of welding a variety of materials including some dissimilar materials. Good set up and correct tooling selection is essential to produce a satisfactory weld. This process is normally used at the manufacturing stage and is generally not considered to be a portable welding process.

Electron Beam Welding

This welding process uses a focused beam of electrons aimed parallel to the fusion faces. As they collide with the solid material their kinetic energy is released as heat which melts the material fusing the surfaces together. The penetration depends upon the material type, intensity of the beam and the velocity of the electrons striking the material.

Generally the process creates less distortion than traditional arc welding processes but relies heavily on good setup and fusion face preparation. Alignment of the beam is crucial to avoid lack of fusion flaws/centreline cracking and for thicker sections sloping in and out of the material may give rise to cavities aligned along the fusion face. This process needs to be carried out under strictly controlled chambers due to radiation hazards and vacuum requirements.